Porsche New Cayenne: An In-Depth Look at the Factory Production Process! (A Summary of the TV Program)

公開日:2018.09.07

New Cayenne Production Process ①

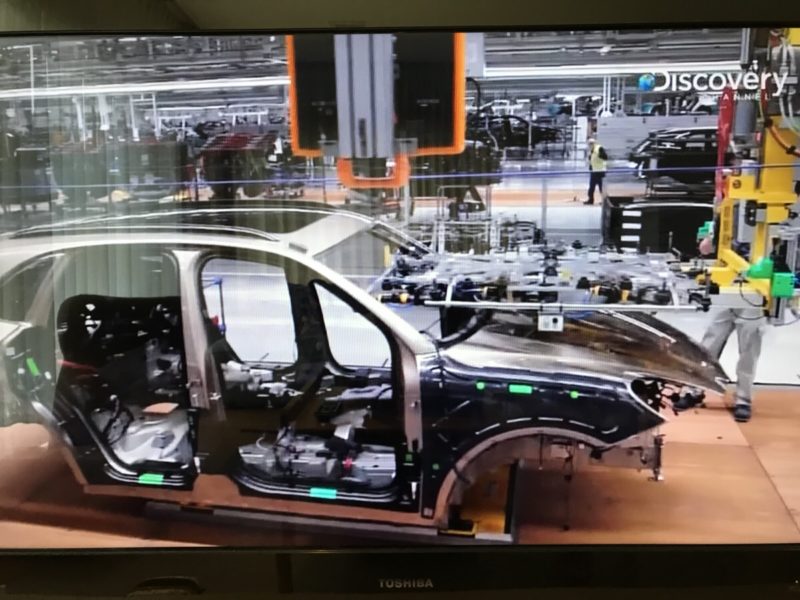

The factory process is divided into four sections: “Press Line,” “Body Manufacturing Line,” “Painting Line,” and “Assembly Line.”

First, on the press line, 750 robots produce 400 body shells per day. Almost all of this process is done by robots, and it takes about 11 hours to make one body shell.

Next, the body manufacturing line takes over. The work passes from robots to human hands. Production is carried out under strict standards, from panel gaps to bolt tightness.

Here, all work is done manually, but to maintain high quality, heavy parts are handled with machine assistance, while assembly is basically completed by hand. After all these steps, the car moves to the painting line.

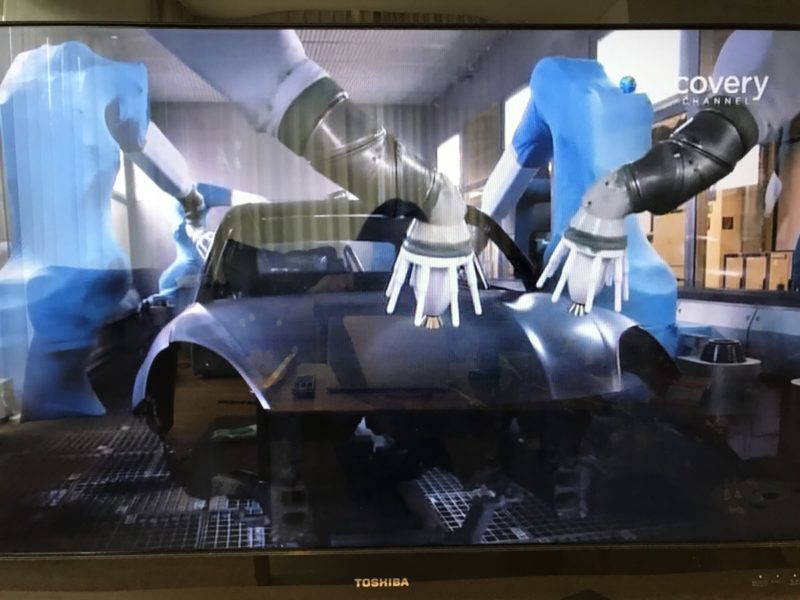

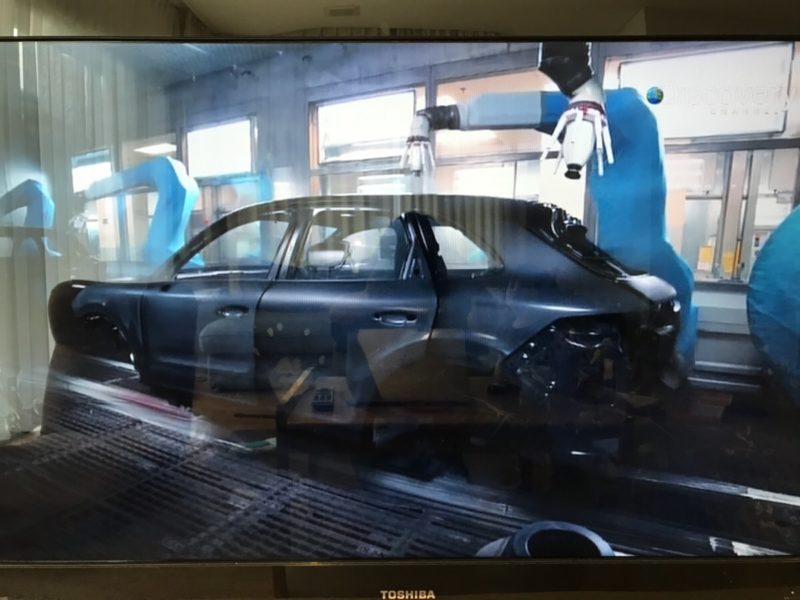

On the painting line, 88 robots paint one Cayenne over 18 hours.

…18 hours to paint one car!? (;゚Д゚)

First, a base coat as thin as a human hair is applied, followed by a clear coat. After this careful priming, the refined painting robots apply the color.

The robot’s head spins at about 50,000 rotations per minute.

I don’t really understand it, but 50,000 rpm sounds impressive (lol).

New Cayenne Production Process ②

After painting, the car moves to the assembly line. Here, the engine, seats, bumpers, and interior are installed. Porsche pays great attention to the working environment of its employees and continuously improves it to be among the best in the industry.

Employees work standing on wooden boards designed ergonomically to make their tasks easier.

The body is suspended at the worker’s height for easy access, and equipment allows comfortable seated work inside the car.

Heavy panoramic roofs and seats weighing over 30 kg are mostly transported by machines, with workers guiding them into place by hand.

Porsche offers a wide range of options with countless combinations, and on this assembly line, parts are gathered according to customer orders and installed by hand.

With around 5,000 parts in total, inventory management is a huge challenge.

Afterwards, the front and rear bumpers, front and rear wheels, and hood are installed, finishing with the emblem.

If I could work at this factory, I’d want to be in charge of the emblem installation (taking the best part at the end lol). The person responsible said, “I’m very proud to be in charge of this task.” I envy them.

New Cayenne Production Process ③

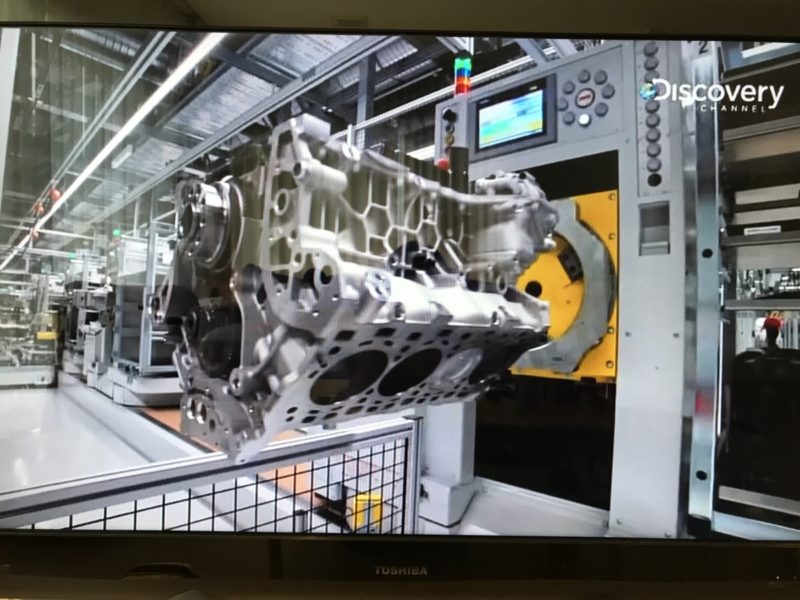

Meanwhile, on the sub-line, the powertrain (the system that transmits engine power to the drive wheels, including engine, clutch, transmission, driveshaft, etc.) is installed. The heart of the car—the engine—is handmade one by one at Porsche’s headquarters factory in Stuttgart, not Bratislava.

In 2015, Porsche invested over 80 million euros to build this factory. While there were just over 100 employees in the early 1950s, the engine manufacturing division now employs 1,200 people. It takes about 6 hours to build one engine, with 200 engines produced daily.

In 2015, Porsche invested over 80 million euros to build this factory. While there were just over 100 employees in the early 1950s, the engine manufacturing division now employs 1,200 people. It takes about 6 hours to build one engine, with 200 engines produced daily.

Completed engines are transported 800 km from Stuttgart to the Bratislava factory.

Since powertrain types vary by grade and engine, pin colors are assigned by engine type to avoid mistakes and improve efficiency. For example, the V6 FSI uses “red,” so parts are installed on red pins to ensure correct assembly.

New Cayenne Production Process ④

The completed powertrain moves to the next stage, the “marriage station,” where the body and powertrain are joined. Usually, there is one marriage station, but this factory has six, ensuring high quality through careful, step-by-step assembly.

Cables are connected, and the interior is finished,

and after 7.5 hours, the Cayenne is finally drivable. Turning the ignition key to start the engine is the best moment for employees, when their long efforts take tangible form. The factory is filled with a sense of accomplishment.

There is one more crucial step for the finished car: quality control checks. Inspectors thoroughly examine the vehicle to ensure there are no issues. Only after passing this check is a Cayenne complete.

Ta-da! (lol)

The Legacy of the New Cayenne

The Cayenne is a 4-door sports car capable of off-road driving. Its introduction drastically changed Porsche’s customer base. It became a car not just for a wealthy few but an ultimate sports car in SUV form suitable for everyday use, broadening its appeal.

Due to its immense popularity, making bold model changes is difficult. Considering the risk of losing loyal fans and users, the third-generation new Cayenne has evolved further without drastically changing its appearance or core features.

Today’s Porsche owes much of its success to the Cayenne. Following Porsche, luxury automakers have all developed, produced, and sold SUVs combining excellent driving performance and luxury. (Even Ferrari is rumored to be launching an SUV.)

The Cayenne’s debut not only saved Porsche but also significantly changed the automotive industry.

That’s the content aired on the program.

I see now—knowing the scale of equipment, processes, and people involved, and that you can buy this for around 10 million yen, it almost feels like a bargain (-_-). If someone handed me 10 million yen and said, “Go build a Cayenne,” I’d never manage it in a lifetime.

When I finished writing this article, I said, “Alright! Finally, I’ve written the Cayenne article!” and my husband joked, “This isn’t a blog post, it’s basically a report article (lol).”

True… someday, I’d love to visit a factory for an actual interview.

このブログが気に入ったらフォローしてね!

Comment ( 0 )

Trackbacks are closed.

No comments yet.