I had a custom car body cover made by Nakabayashi Kogyo by bringing in my actual car!

公開日:2018.11.13

Hello everyone! I’m Mina, the administrator of the blog “Welcome Home, PORSCHE.” Recently, I had the opportunity to visit Nakabayashi Kogyo, a long-established manufacturer of body covers, to have a custom body cover made for my Panamera. Thanks to their generosity, I was allowed to document the entire process from measurement to creation, and I’m excited to share that experience with you.

1. What is Bringing in Your Car for Measurement?

Free Body Cover Gift!

Previously, we ordered body covers from Nakabayashi Kogyo for our Porsche 981 Boxster GTS and Mercedes-Benz SL500 (R129), and even my husband, who is usually quite critical, was full of praise.

“Let’s order a body cover for the Panamera too!”

However, when I contacted them, I was informed that they didn’t have a pattern for the new model after the full model change.

Nakabayashi Kogyo currently has patterns for about 3,000 types of body covers, but naturally, there are some models they don’t have patterns for. If you bring in a relatively new model after a full model change or a model they are interested in, they will give you the first body cover for free as a token of appreciation for your cooperation in the measurement process. (If you don’t need the body cover, you can receive a VJA gift card worth 10,000 yen on the day of completion.)

Additionally, photos of the car and the cover after installation will be published later on the “Minkara” blog as part of Nakabayashi Kogyo’s production diary.

The offer of a “free first body cover” was too tempting to resist, so I gladly decided to bring in my car.

Three Courses for Bringing in Your Car

When bringing in your car, you need to choose one of the following three courses:

① One-Day Completion Course

Bring your car in at 9 AM on a weekday and have the work completed in one day. Recommended for those coming from afar.

② Multiple Visits Course

Bring your car in for about 40 minutes per visit, 3 to 5 times, or more (the average is 4 times) until the pattern is completed. Recommended for those who find it difficult to leave their car for a whole day or live nearby.

③ Overnight Course

Leave your car for over 24 hours and pick it up the next day (or the day after). This course is most recommended as it allows Nakabayashi Kogyo to take ample time to aim for a perfect pattern.

I chose the ③ “Overnight Course.”

When bringing in your car, you are responsible for the round-trip gasoline and transportation costs to Nakabayashi Kogyo, but they will provide a loaner car while your car is with them. (Nakabayashi Kogyo covers the gasoline costs for the loaner car.)

Why Go Through the Trouble of Bringing in Your Car?

Initially, I was surprised at the idea of bringing in my car. Bringing in your car involves coordinating schedules, arranging a loaner car, the time required for sample creation, and securing the necessary personnel, which is a hassle for both the car owner and Nakabayashi Kogyo.

Moreover, leaving your car overnight carries risks, albeit minimal, of “scratches” or “theft.”

Even though our Panamera is a new model after a full model change, the size and design aren’t drastically different from the previous model. So, I honestly thought, “Can’t they just base it on the previous model’s pattern and verify the car’s size with the manufacturer’s catalog?”

When I asked President Nakagawa about this, he responded:

“Indeed, measuring by bringing in the actual car is a hassle. However, the most important role of a body cover is to ‘protect the car.’ To achieve this, we believe it’s necessary to create the body cover carefully with our unique methods and senses, rather than relying on data calculated from the manufacturer’s catalog values. All the patterns we have now are based on actual cars, and conversely, we can’t create a cover for a car unless we meet it in person.”

I see… This is the pride of a manufacturing company.

However, due to the popularity of bringing in cars for body cover measurement, they have temporarily halted accepting new requests. They plan to resume in the new year.

2. On the Day of Measurement

Heading to Nakabayashi Kogyo in the Morning

So, on the morning of the day, I headed to Nakabayashi Kogyo with my Panamera. The weather forecast was sunny all day. I was relieved because if it rained on the way, it would have been a hassle to wipe off the rainwater upon arrival.

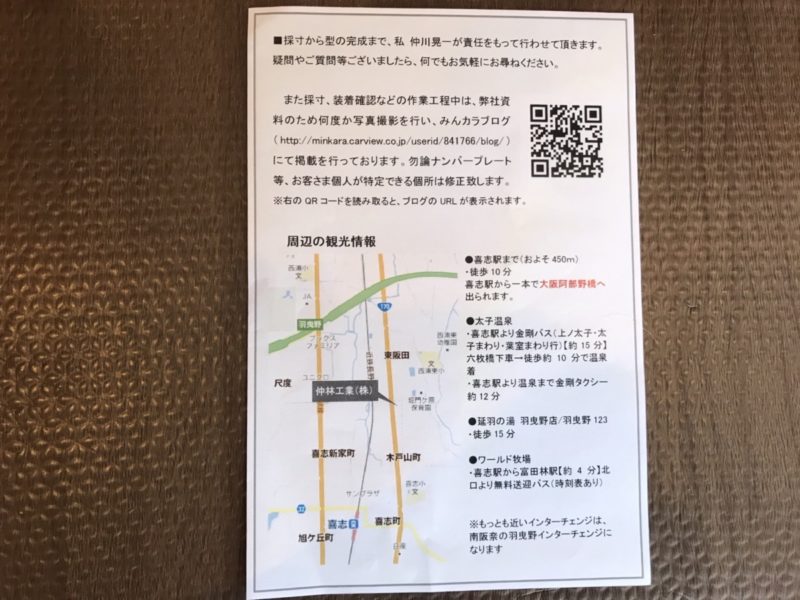

Nakabayashi Kogyo’s office and factory are located about 3 minutes from the Habikino Interchange on the Minami-Hanna Road. I arrived without any trouble and, upon entering, saw many boxes of body covers waiting to be shipped.

Due to the impact of a large typhoon in September this year, there was a surge in orders for body covers, and they couldn’t keep up with the shipments. (By the time this article is published, things should have settled down.)

After greeting Mr. Nakagawa and the staff, I was handed three documents.

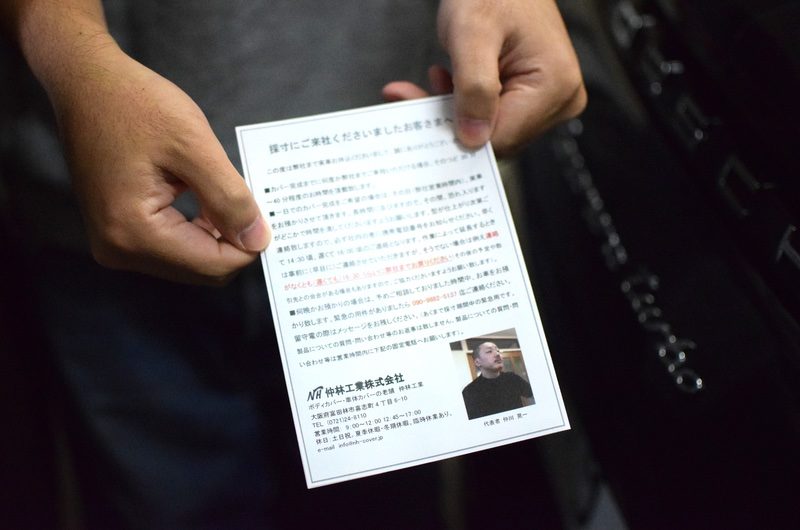

The first document was titled “To Customers Visiting for Measurement,” detailing precautions for bringing in your car, estimated time required for measurement and creation, and more.

On the back, there was even tourist information for those on the one-day completion course! How thoughtful (laughs)!

The second document was a consent form.

According to Mr. Nakagawa, “Initially, we didn’t have a consent form, but we were advised to prepare one just in case.” The consent form included:

・Although we will try not to touch the car’s body as much as possible during measurement, there may be some contact.

・The measurement process and the completed cover will be photographed and published on the “Minkara” blog.

・If there are any pre-existing scratches on the car, please confirm and report them in advance.

・If the work is extended, we will contact you in advance.

The third document was an application form for a loaner car, provided only to those who need one.

Step 1: Measurement

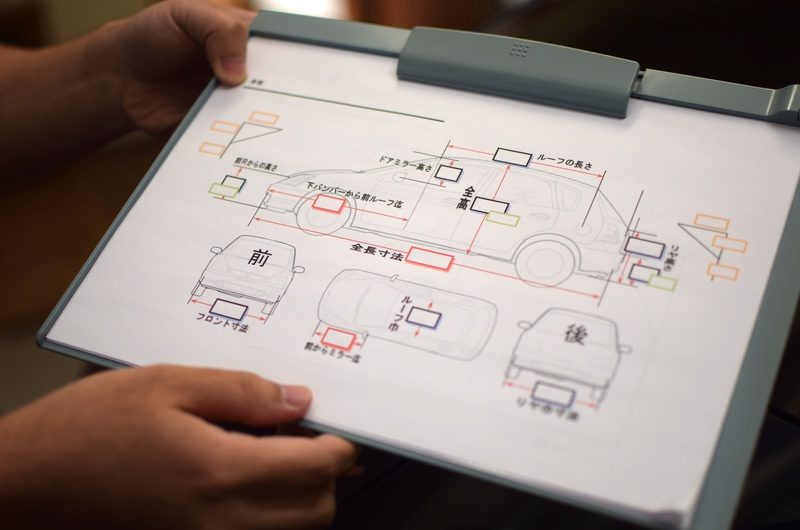

After reviewing and signing the documents, the measurement began. Several sheets were prepared to record the detailed dimensions of the car.

Following these sheets, two staff members measured the car while Mr. Nakagawa recorded the numbers. Both Mr. Nakagawa and the staff were in serious mode, so I quietly observed without interrupting.

I was amazed by the meticulousness of the measurement points. “Wow, they measure even that part!?” They measure over 30 to 40 points in total.

However, since everyone was experienced and worked in perfect harmony, the measurement process itself was completed in about 5 minutes.

Step 2: Sample Creation (First Attempt)

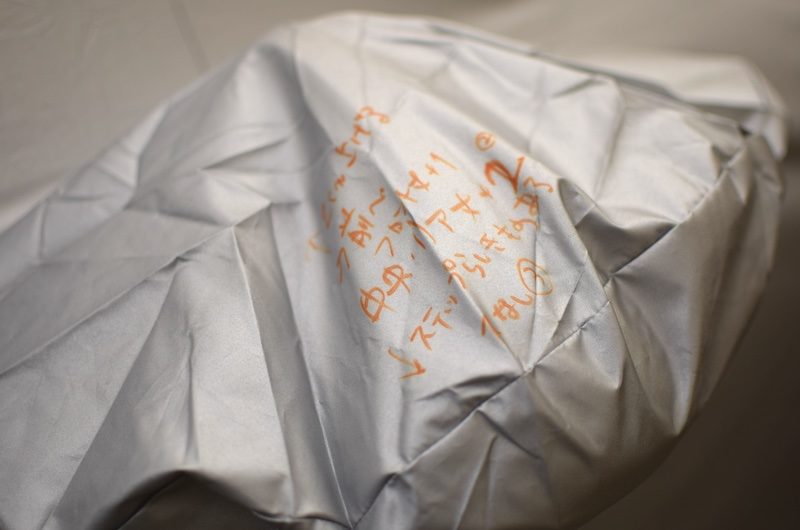

After the measurement, the first sample creation began. Normally, it takes about 30 to 40 minutes for cutting and 30 minutes for sewing, totaling about an hour and a half. However, since I was documenting the entire process, they had prepared a sample of the 970 Panamera (previous model) in advance. (The fabric was wrinkled as it was a previously made and stored sample, but the actual fabric is much nicer.)

When the sample body cover was placed on the car…

This is how it looked.

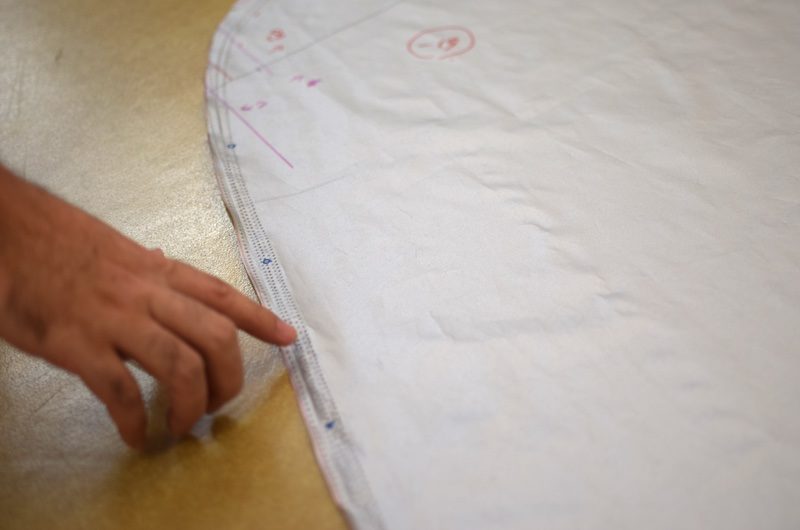

Step 3: Marking

Mr. Nakagawa carefully checked the tension and wrinkles of the covered body cover.

To my untrained eye, the 970 pattern seemed to fit perfectly, so I said, “This looks fine to me…” Mr. Nakagawa replied, “No, it doesn’t fit at all.”

“For example, there’s a sag here. If rainwater or dust accumulates here, the weight can cause the fabric to deteriorate, leading to damage to your car.”

“Also, the bonnet and rear areas are a bit tight. If we don’t allow a little more room here, it will put stress on the car. And it seems the mirror position is slightly different between the old and new models. We need to adjust that too.”

Although I wasn’t bothered by it at all, it seemed that this stage was still far from Mr. Nakagawa’s goal.

After that, they marked the areas that needed adjustments with notes like “cut this part by this much.”

This marking is minimal, so it doesn’t affect the car body at all. After completing all the checks, they removed the body cover from the car.

Step 4: Sample Creation (Second Attempt)

Next, they completely unraveled the seams of the body cover. “What!? You’re unraveling everything!?” I exclaimed, to which Mr. Nakagawa replied, “Yes, we unravel everything and make the necessary adjustments based on the markings.”

Following the notes like “cut this much,” they cut and adjusted the fabric, then spent another 30 minutes sewing it.

They then covered the car again, checked, marked, unraveled, adjusted, and sewed… This process is usually repeated 2 to 3 times. It takes quite a bit of time for these adjustments.

Some patterns fit perfectly on the first try, but that’s rare.

The final decision of “Yes, this is it! Let’s go with this!” is made by President Nakagawa, but:

“Even if the dimensions are correct and everyone says it’s good enough, if it doesn’t feel right to me, I’ll redo it as many times as necessary until it does.”

Amazing…

However, Porsche patterns are relatively easy to finalize. As I wrote in a previous interview article, Porsche’s design is natural and without strain, so it doesn’t require major adjustments. On the other hand, unique designs like supercars are very challenging.

| →【Next Page】The Perfect Body Cover is Finally Complete the Next Day!! |

このブログが気に入ったらフォローしてね!

Comment ( 0 )

Trackbacks are closed.

No comments yet.